Dust and chemical application on seed is an extremely sensitive issue in Europe and is emerging as a problem in other parts of the world.

Crop protection products registrations have been temporarily put on hold (with huge financial implications) due to the two major pesticide bee related incidents that have occurred within the last 10 years. This is the reason that Hoopman did rebuild their rotary fluid bed system to make “low cost” conditioning/de-dusting possible!

By adding a hoopman conditioner to your already in place treatment system you can easily de-dust and cure your treated seeds.

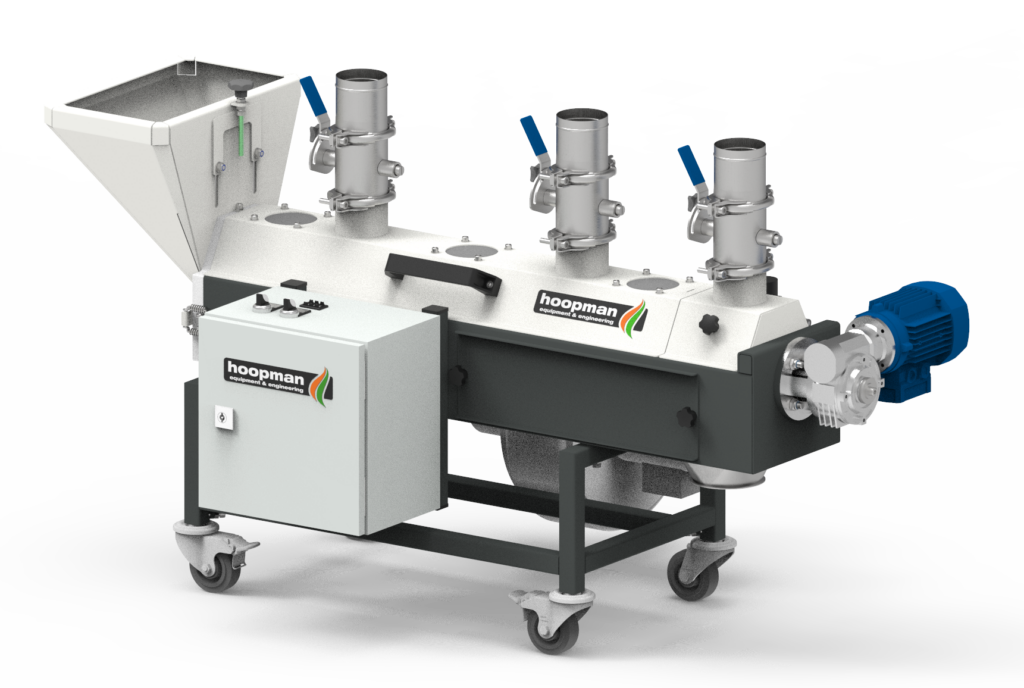

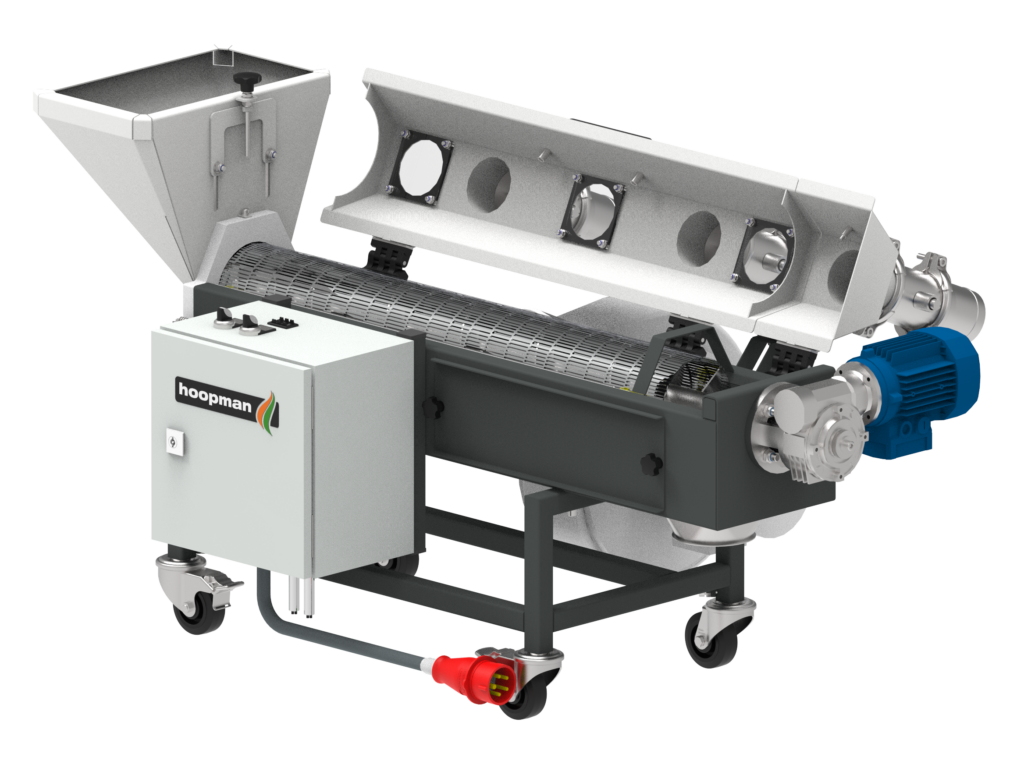

One of our smallest conditioners is the RFBC140-LAB, this conditioner has a capacity from 50 up to 150kg/hr (Depending on your conditioning time). By pushing ambient air through the seeds with a fluidised bed principle we have a good de-dusting and controllable and repeatable curing of your coating layer.

This small conditioner is perfect to develop protocols for bigger lines. We have several bigger machines available from 1 to 25t/hr. (Depending on the actual conditioning time required)

Advantages

- Conditioning and de-dusting in one run

- Cured film coating will allow products applied on the seeds to “hold better”

- Cured film coating has much better flow characteristics in both seed packing line and in planters

- Better control of application of products on seed

- Can be easily adapted to already in use film-coating, seed treatment system

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.